About Vickers Hydraulics and Products

As a worldwide leader, Vickers Hydraulics designs and manufactures a comprehensive line of reliable, high-efficiency hydraulic systems and components. They globally market as a complete line of reliable, high-efficiency hydraulic components through the most extensive distributor network in the fluid power industry.

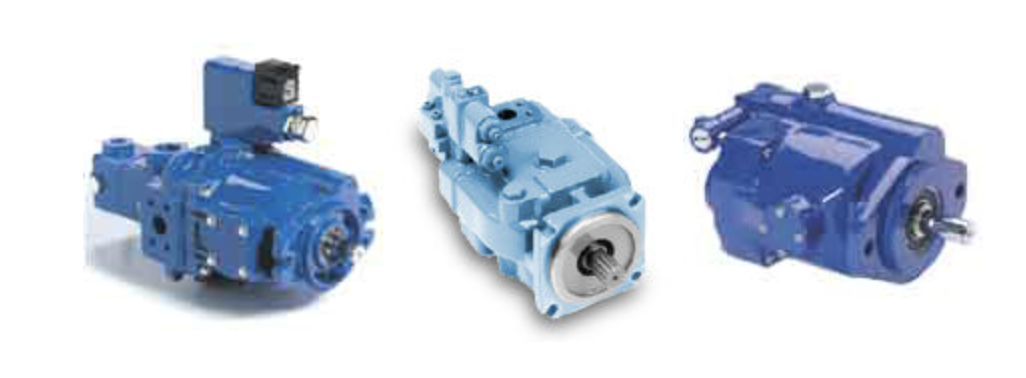

Customized performance on every application assures most complete line pf standard fluid power pumps ever offered to industry so there is no need to compromise on performance. Your choice of pump is backed by Vickers know how, assuring that you get the exact pump needed for the job.

There are many design series, enabling you to pick the best pump for the job. They include single, double and combination pumps.

Advanced Manufacturing

Extensive use of powdered metallurgy and other advanced manufacturing techniques permits them to offer in-line series piston pumps at substantial weight and cost reductions to you so whether fixed or variable displacement, these pumps feature high volumetric efficiency and pressure range of 1000 to 5000 psi. Various types of pressure control devices that they manufacture, tailored to you specific demand.

Exclusive hydrocushion design reduces pressure shocks from the system. Operate these valves remotely for unloading and sequencing, or directly for pressure relieving and reducing. Precise volumetric control is possible with temperature and pressure compensated flow control valves.

Vickers Hydraulics Valves

Vickers Hydraulic Valves are available with or without integral relief valve section and are suitable for pressures up to 3000 psi. Models are available to meet any requirement. Their directional valves offer the ultimate in compactness and versatility of application for many directional control requirements f hydraulic machinery. Ruggedness of design, controlled manufacturing quality and world-wide parts interchangeability are important parts of the overall story. Even on the most exacting industrial applications, you’ll find our directional controls keep your maintenance simple and downtime at a minimum. When your application needs rotary power, they have a hydraulic motor to do the job.